Oxine (Water Treatment & Disease Control)

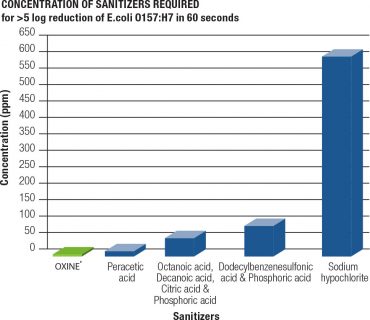

Oxine is a multipurpose liquid disinfectant which is many times more powerful in eliminating micro organisms than common chlorine based materials or hydrogen peroxide.

The beauty of this product is that it is a very powerful oxidiser yet it leaves no harmful by-products behind.

When Oxine (a patented stabilised Sodium Chlorite solution) is activated with citric acid it forms a stock solution liquid which emits Chlorine Dioxide gas (ClO2) – a very powerful Oxidising agent.

(Chlorine Dioxide (ClO2) derived from Oxine is not to be confused in any way with swimming pool Chlorine, or industrial strength applications of low grade ClO2 – they are totally different)

This ClO2 stock solution is then added to the body of water requiring treatment. The ClO2 immediately takes action and begins oxidising any harmful micro organisms it comes in contact with.

It is the Oxygen in the molecule ClO2 that is so active. After the oxidation of microorganisms takes place the Chlorine (Cl) in the ClO2 molecule finishes up being combined with Sodium (Na) to form a harmless degradation product – common salt (NaCl).

It is the powerful oxidation properties of the ClO2 molecule and the harmless by-product it leaves behind (common salt) which makes Oxine an excellent product for water treatment in hydroponics.

The common salt left behind as a by-product of the oxidation process is of low toxicity and can easily be monitored and removed from the system should they ever built up to unwanted levels. In hydroponic systems these levels are usually negligible provided there is not an elevated content of sodium already present in the water supply.

Oxine overcomes the shortcomings of all other Chlorine-based products which allow troublesome organochlorines to form when chlorine reacts with organic material.

The Oxine product is unique in that the patented method of manufacture and stabilisation produces a product ideally suited for use in horticulture.

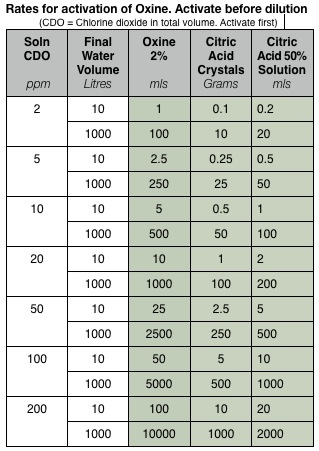

The Oxine application rates for hydroponics are as follows:

2ppm – The standard dose rate for fully sanitising water supplies used for hydroponic systems or human consumption. Can be directly added as a calculated dose to a fresh water holding tank. Targets Pythium, Phytophthora and similar water borne pathogens.

5ppm – Oxine is approved in most places for use at 5ppm, activated with Citric Acid, for use in post-harvest wash solutions. Crop is immersed in the wash bath for a few minutes. As well as reducing browning it will eliminate all organisms and pathogens of concern, including E coli. Oxine degrades to 1-2ppm of common salt and leaves no detectable residues.

20ppm – For flushing through drippers, drip tape and other pipework to sterilise them between crops or when disease problems occur. Great for removing biofilm from pipes, gullies and drip systems. (Plants must be disconnected from the gullies or drippers and pipework must be well flushed with fresh water before reconnecting to the crop). When used with a wetter/spreader the level of contact and effectiveness increases.

Latron B1956 is the best surfactant to use.

The amount of surfactant required varies quite a lot depending on the hardness and TDS of the water. The best guide is to gradually add up to 5ml/1000L while the tank is being mixed. Then monitor. The correct rate is determined when a stable layer of foam forms on the surface of the tank solution and spreads 300-600ml from the flow of water that comes back into the tank during mixing. Most tanks only need a maximum of 10ml/1000L. If too much foam is formed the tank must be purged and diluted.

20ppm – Media Drench (Fungi Only) – For flushing through reusable media to sterilise it before it is used for the next crop e.g coconut coir, pumice, scoria

50ppm – 100ppm – Media Drench (Fungi and Bacteria) – For flushing through reusable media to sterilise it before it is used for the next crop e.g coconut coir, pumice, scoria

100ppm – For disinfecting processing lines, greenhouse floors or harvesting equipment. As a soak bath additive to sterilise growpots and propagation trays and other equipment. Will loosen stubborn organic matter and biofilm. No rinsing required after application. Can also be applied as a fine mist. Ensure surfaces are wet for at least 1 minute.

Contact Pure Hydroponics for more information on this world-class multipurpose disinfection product.

Pricing

20 Litre Oxine NZ$415.00 + GST

2Kg of Citric Acid Crystals (For Activation) NZ$20.00 + GST

Discounts available if purchasing multiple units

200 Litres of Oxine NZ$P.O.A

Oxine Test Strips (Packet of 50) $83.50 + GST

How to Fully Sanitise Your Freshwater Holding Tank

- Oxine is perfect for fully sanitising the water in storage tanks that are used to hold dam water, bore water, rainwater, or any water supply that may have contamination.

- Simply work how much water is in your tank. https://purehydroponics.com/wp-content/uploads/2012/05/Calculating-The-Volume-of-Nutrient-Solution-in-a-Tank1.pdf

- Measure out the amount of Oxine you require to treat the tank volume at 2ppm strength. (See 2ppm rates in table below). Add to a small bowl.

- Measure out the amount of citric acid crystals you need to activate that amount of Oxine.

- Add the Citric acid crystals to the Oxine in the bowl.

- Stir the solution and let it sit for exactly 10 minutes to activate the Oxine (It turns yellow – don’t breathe the fumes).

- Then add the activated Oxine solution to a bucket of water with a small hole in the bottom and slowly drip that into your water holding tank. Agitate the tank as it is dripped in to ensure good mixing (e.g use an air pump and airstone or a stirring pump, or refill the holding tank with fresh water as the Oxine is being added but don’t exceed the water volume you based your calculations on).

- 12 hours later the contents of the tank will be fully sanitised and ready to use in the hydroponic system.

- Don’t allow any untreated water to be added to the treated water holding tank until it is ready to be refilled and redosed. In some situations, two holding tanks can be utilised – One for treated water and one for untreated water awaiting treatment. Then alternate between the two. This ensures you always have a good volume of treated water on site.

- At 2ppm strength the tank water is safe on live plant roots and is also safe to use for drinking water.

Information Articles

Tanner Study – Disinfection Potency

Benefits

- Ultra high,broad-spectrum antimicrobial activity

- Uniquely effective against biofilm

- Effective over a broad pH range (1-10)

- Low corrosion potential at use concentrations

- Resists neutralization due to organic load

- Completely soluble in water

- Does not chlorinate (no THM formation)

- Long lasting bacteriostatic activity

- Excellent deodorant

- No effect on organoleptic properties

- No effect on nutritional quality

- KOSHER certified

- Economical to use

- Can be used with automated delivery systems

- Safe for applicators (PPE required)

- No unusual stipulations on storage

- Organic certified

Dose Rates for using Oxine 2% Grade are listed below.

Oxine must be activated for 5 minutes when using 50% Citric Acid Liquid

Oxine must be activated for 10 minutes when using Citric Acid Crystals.