Filtration

All water sources and the nutrient solutions used in hydroponic systems should be filtered with an effective Filtration system to maintain a high level of cleanliness at all times.

An effective filtration system reduces the likelihood of disease in a hydroponic crop and also means that hydroponic systems can be kept cleaner for longer with less maintenance.

The water used in hydroponic systems can come from a variety of sources:

River water, dam water, town supply, rain water collected off greenhouse roofs, bore water.

Each source will vary in clarity and quality.

A laboratory water analysis and visual inspection is the best starting point to determine the organic loading of your water source and its quality.

A laboratory analysis may determine that the water is unsuitable for hydroponic growing due to excessive elements such as sodium or iron. This may mean that additional water treatment or filtration is required or another water supply may need to be considered all together if the proposed source is considered to be too expensive to treat.

The water supply is assessed in sequence from the source right through to the point where it is used in the hydroponic tank. Different filtration and treatment equipment is added as required. These various pieces of equipment are covered as follows:

1) Gravel Media Filters

These types of filters are commonly used when there is a heavy organic loading in the source water e.g. from Dam or river water.

The Gravel Media Filters are made of epoxy coated steel with two inbuilt chambers for efficient filtration and backflush uniformity. The top chamber contains the gravel media and this is separated from the bottom chamber by a layer of conical mushrooms. The mushroom design provides thorough backflushing with equal pressure throughout the entire gravel media bed whilst preventing the gravel media from entering the bottom chamber. The source water flows through the gravel media from the top chamber to the bottom chamber and any algae or other organic particles are captured in the gravel. A high percentage of harmful pathogens are also able to be removed from the source water during this capturing process. After a certain period of operation the filter can be back flushed which frees the captured organic material from the gravel and allows it to be discharged from a separate outlet without losing any of the gravel or contaminating the already filtered water.

The Gravel media filters can be installed singularly or in series with extra units added on depending on how contaminated the water is.

1. Water inlet

2. Water

3. Sand bed

4. Water outlet

5. Filtration

6. Service port

7. Media filling

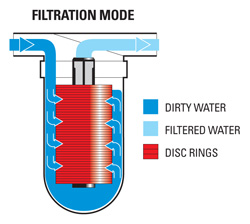

2) Disc Filters

For water sources that are less contaminated (e.g bore water or rainwater collected off roofs), a simple disc filtration process is all that is required.

Manual Disc Filters are engineered for efficient operation year after year with practically no maintenance. Plastic rings are stacked together inside a plastic outer case creating a cylindrical filter element. Each ring has a series of fine grooves on its surface which allows water to pass through under pressure. During filtration, the rings are compressed together, effectively filtering the water as it passes through.

Manual disc filters can be used as a stand-alone units or combined to form modular filter batteries.

Available sizes 3/4” (20mm) to 6” (150mm) with filtration grades from 400 to 20 (micron).

3) Water Sanitation

Once the source water has been filtered it is then held in a water holding tank. It should then be treated with a suitable water sanitiser e.g Chlorine Dioxide, Ozone (see the section: Water Sanitation Products). One holding tank should contain the filtered, unsanitised water, with further tanks to hold the water undergoing sanitisation and the final treated water. After filtration and sanitisation the water is then clean and pathogen free and is ready to be used in the hydroponic system.

4) Screen Filters

After the source water has been filtered and treated it is then released into the hydroponic mixing tank on demand via a ball cock valve. Nutrient stock solutions and pH corrector are then added to the water at the correct levels before it is pumped to the crop.

As the solution is pumped to the crop growing in the hydroponic system it should firstly pass through a screen filter. This consists of a plastic outer case, usually with a cylindrical 130 micron stainless steel mesh screen inside. This screen captures any undissolved nutrients, sediment or organic matter (especially in recirculating systems) before it reaches the crop. This helps to prevent the blocking of drippers and microtubes and reduces the build up of biofilm in gullies and pipework. The outer casing on screen filters can easily be opened and the screen can be removed for easy cleaning which only takes a few seconds to complete.

5) Filter Bags

These specially made heavy duty filter bags can be suspended over any non pressurised return pipe or drain to capture organic matter before it has a chance to contaminate a waterway or catchment tank. The bags are commonly used on the retun pipe in NFT systems to filter the nutrient solution as it gravity feeds back to the mixing tank. The Filter bags are also used on the runoff catchment systems in Drip Fertigation systems to filter out any contaminants that may flow from the greenhouse drains into the runoff catchment tank.

Once full of waste matter the bags are easily unhooked, emptied and cleaned.

Available in two sizes – Medium or Large.

Please talk to Pure Hydroponics for advice on a suitable filtration system or to arrange the laboratory testing of your water supply.